Introduction to MakeItFrom

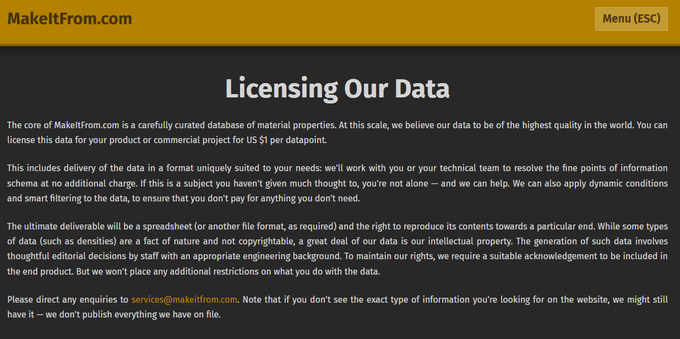

In the world of metal fabrication, selecting the right material is crucial for ensuring the quality and durability of the final product. MakeItFrom, a small but resource-rich company, offers a comprehensive material properties database that has been a valuable tool for fabricators. However, its user interface remains decidedly pre-AI, which can make navigating this wealth of information a bit cumbersome.

Enhancing MakeItFrom with AI

The potential of combining MakeItFrom’s database with a Large Language Model (LLM) is immense. By integrating AI, users can effortlessly call out the right alloy for any job, simplifying the sourcing process significantly. This integration can transform the user experience, making it more intuitive and efficient.

AI in Material Science

AI has been making waves in various fields, and material science is no exception. Companies like Orbital Materials are leveraging AI to discover and design new materials, including batteries and carbon dioxide-capturing cells. Their proprietary AI model, Linus, trained on a diverse dataset of simulations and materials, enables rapid and efficient material design through natural language instructions.

Fluent Metal: A Case Study

Another notable example is Fluent Metal, which uses liquid metal 3D printing technology. This approach offers high precision, adaptability, and compatibility with a broad spectrum of metals. The integration of AI can further enhance the efficiency and sustainability of their processes, making them a strong competitor in the aerospace and medical device industries.

Speeding Up Metal Printing

Researchers at MIT have showcased a new approach to liquid metal printing (LMP) for rapid and large-scale aluminum object fabrication. This method, supported by AI, significantly increases printing speeds and allows for larger object sizes compared to existing metal 3D printing methods. The potential disruption to traditional metal fabrication methods is substantial, expanding the applications of 3D printing in construction and manufacturing.

Atomic Industries: Bridging Bits and Atoms

Atomic Industries is another company making strides in this field. Their AI-powered software automates tool and die making in manufacturing, combining AI with physics-based simulations to optimize tool and die design. This innovation has the potential to revolutionize manufacturing efficiency and cost, aligning with trends of automation and AI adoption in manufacturing.

Metalbook: Bridging Supply Chain Gaps

Metalbook offers a SaaS B2B platform for metal manufacturing and procurement, covering the entire metal supply chain. The integration of AI/ML for optimization can improve efficiency and transparency, addressing pain points in the metal industry and potentially disrupting traditional supply chain management.

Conclusion

The integration of AI into material science and metal fabrication is not just a trend but a transformative force. Companies like MakeItFrom, Fluent Metal, Orbital Materials, Atomic Industries, and Metalbook are leading the charge, demonstrating the vast potential of AI to enhance efficiency, sustainability, and innovation in the industry. As AI continues to evolve, its impact on metal fabrication and material science will undoubtedly grow, paving the way for new advancements and opportunities.

Related Articles

- Top 5 Best AI Tools for Business

- Exploring the LLM Engineer’s Handbook: A Comprehensive Guide for AI Researchers

- Create Financial Spreadsheets in a Click with AI (Free)

- AI Mailer

- Top 5 AI Tools for Productivity

Looking for Travel Inspiration?

Explore Textify’s AI membership

Need a Chart? Explore the world’s largest Charts database